0%

Emissions

100%

Efficiency

ZERO

CO2

CORE

RECYCLED

Discover the innovative process behind ZECO₂RE cores.

How we produce magnetic cores using factory leftovers

Learn more about our cutting-edge production, developed through the knowledge and innovation of our engineers.

Safety and Quality

We are dedicated to maintaining the highest standards in both areas to ensure the excellence of our products and services.

Efficiency Meets Sustainability

100% efficiency with ZERO emissions in production.

Discover ZECO₂RE: The Future for your offcuts

ZECO₂RE sets a new benchmark in magnetic core production with unmatched efficiency and zero emissions. Our cutting-edge sorting and laser cutting technologies guarantee precision and quality, positioning us as pioneers in sustainable manufacturing. The production process consists of the following sequential stages:

- Material Inspection and Sorting: thanks to automated sorting, the process is significantly faster and more accurate, ensuring that every offcut meets our strict quality standards before advancing to the next stage. Our state-of-the-art sorting machine evaluates each sheet based on key criteria: length, thickness, and core losses (W17/50), enabling optimal selection for high-efficiency core production.

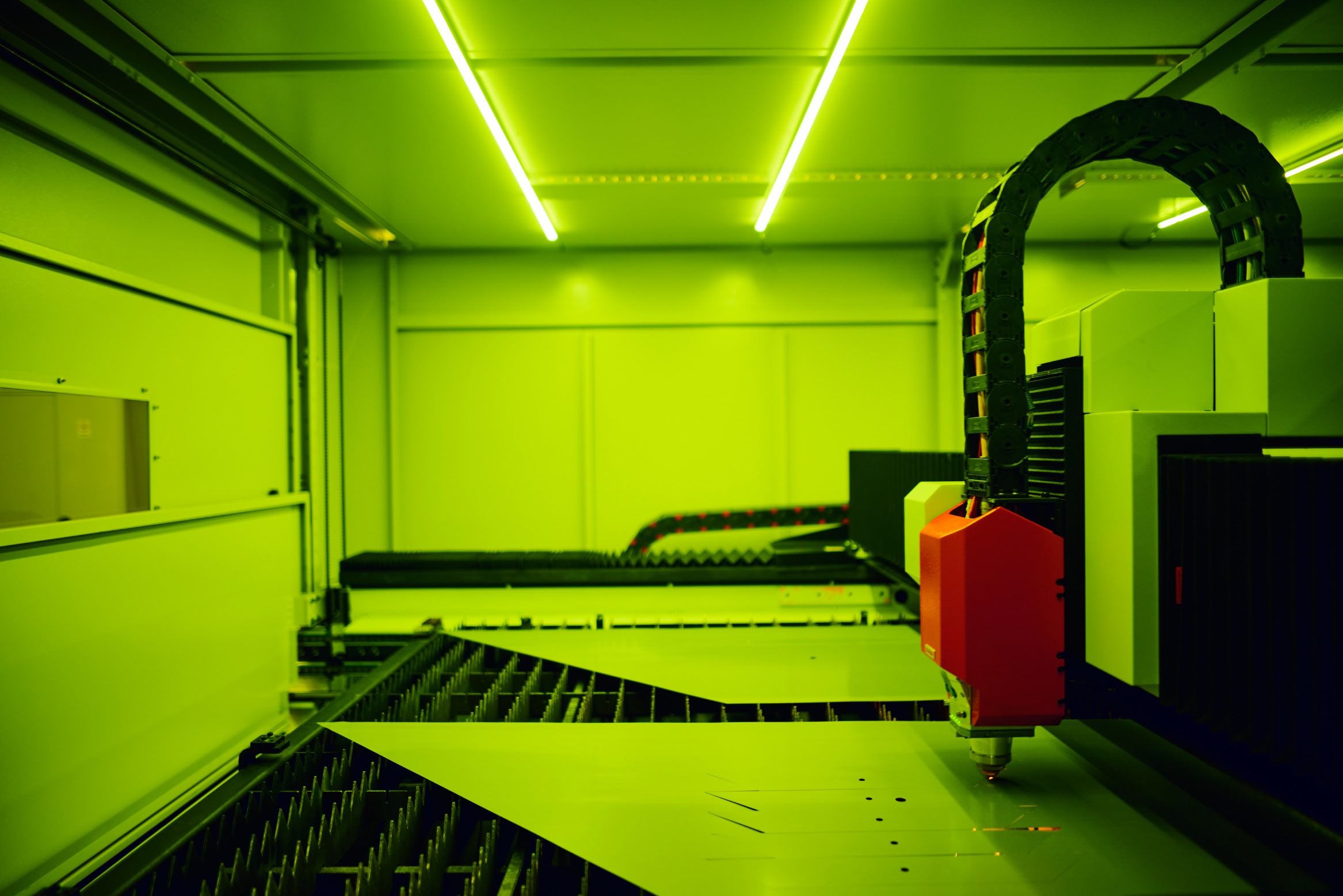

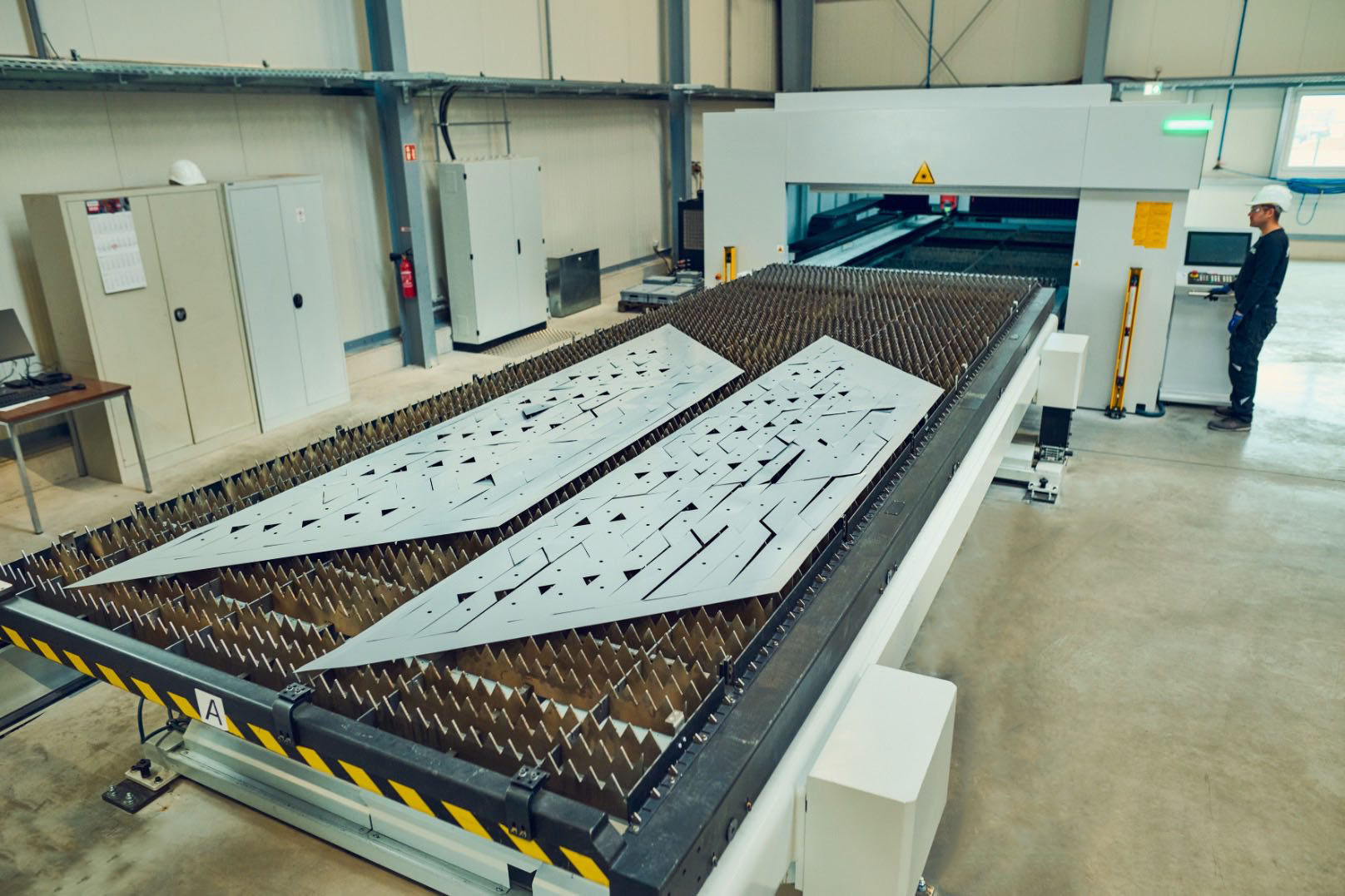

- Precision Laser Cutting: The sorted sheets are then cut to exact specifications using high-precision laser cutting machines, ensuring minimal waste and maximum accuracy.

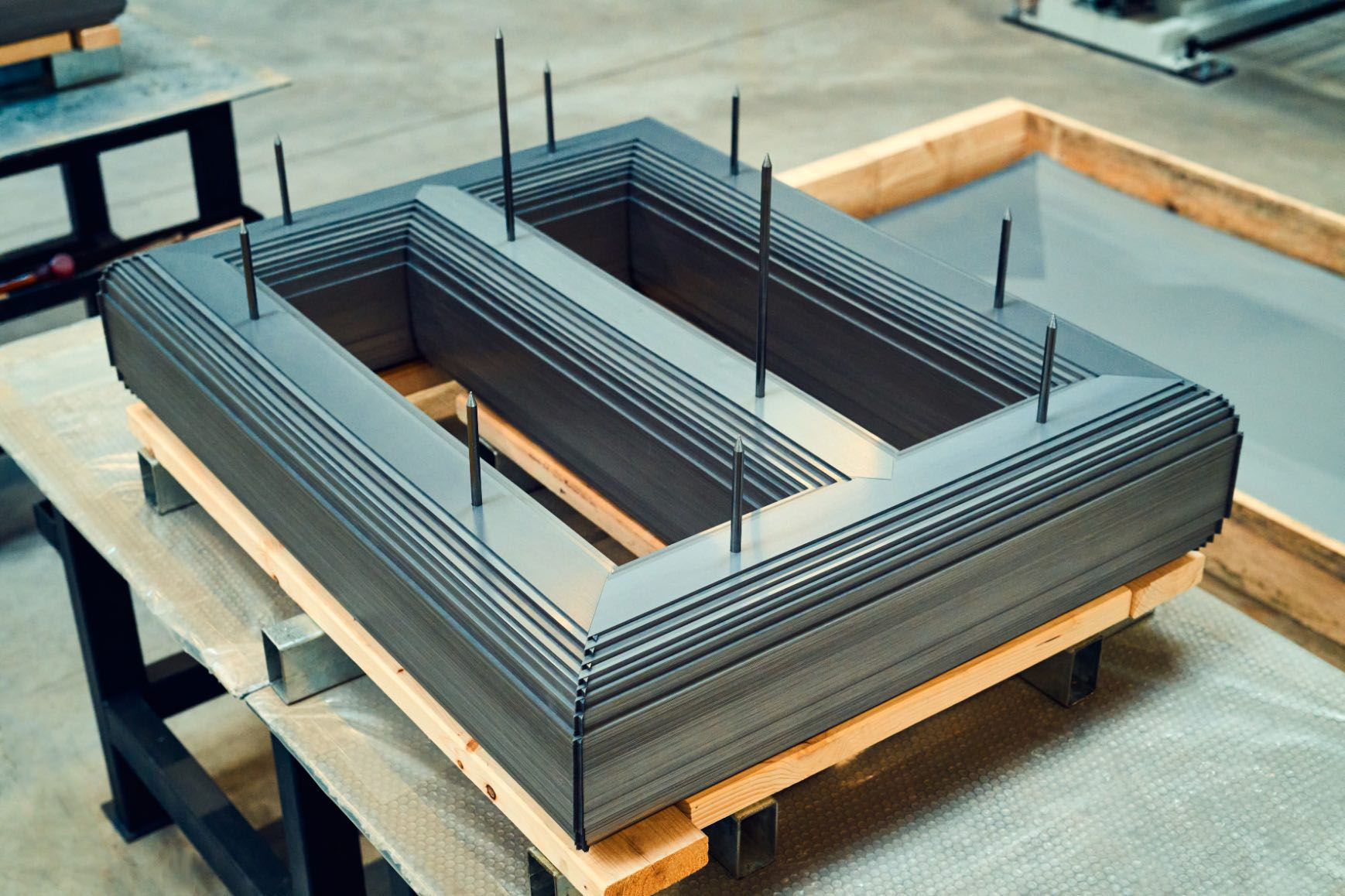

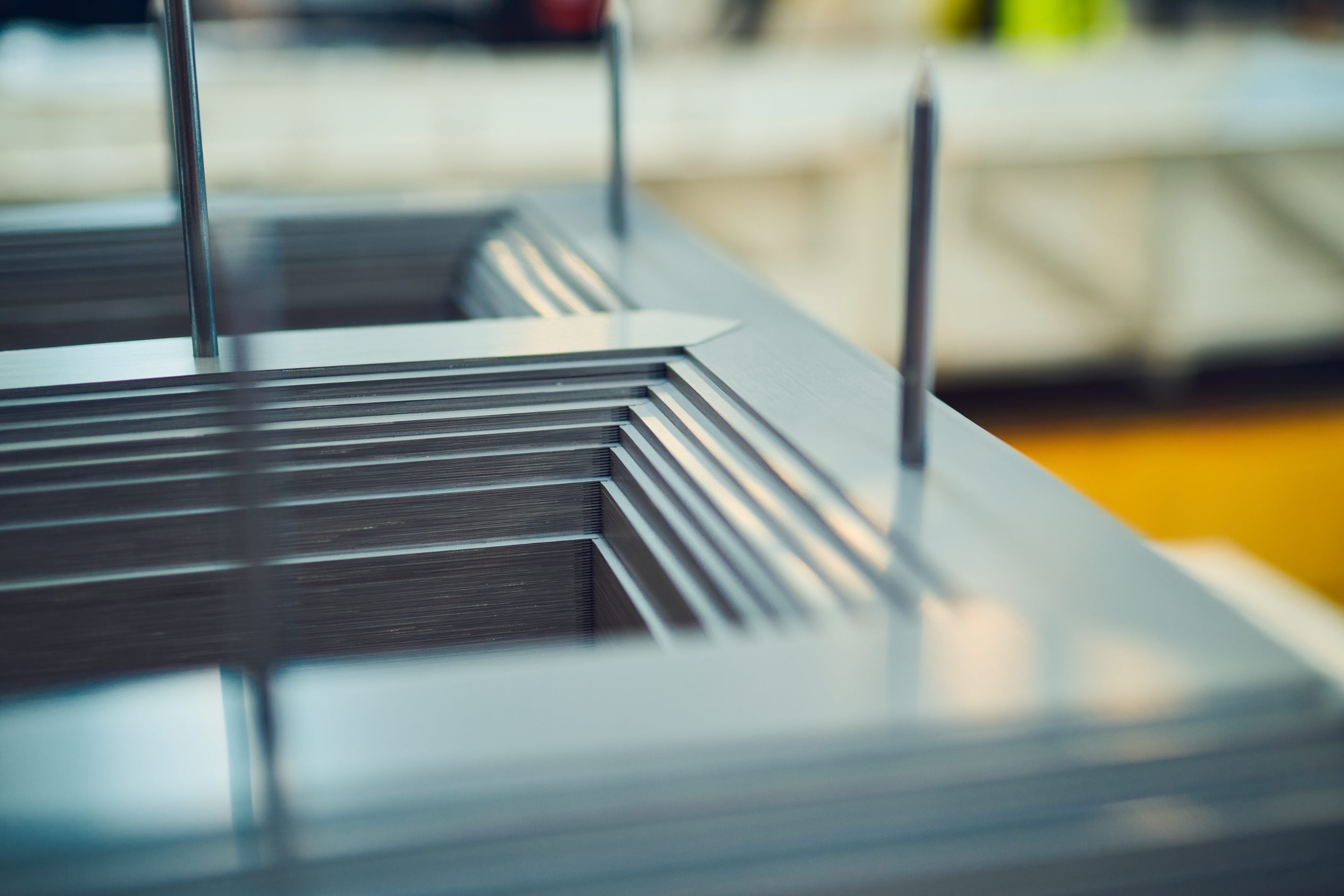

- Core Stacking and Assembly: Cut components are carefully stacked and assembled into the transformer core, following strict alignment and layering protocols to maintain magnetic performance.

- Final Testing and Quality Control: The completed magnetic core is subjected to comprehensive testing to verify its electrical and structural integrity before approval for use.

Safety & Quality

In magnetic core production, safety and quality are fundamental. Our operations are guided by strict industrial standards, ensuring the safe handling of materials, precision manufacturing, and comprehensive quality control. At the heart of this process are our highly educated and skilled employees, whose expertise and training ensure that each core meets the highest levels of reliability, efficiency, and safety.

Environmental responsibility

Sustainability is at the core of our production philosophy. By manufacturing magnetic cores from production leftovers, we significantly minimize yours and ours environmental footprint. This circular approach not only optimizes resource efficiency but also supports responsible manufacturing practices. Equally important is our commitment to keeping material flows within Europe—reducing transport emissions, strengthening local supply chains, and contributing to the resilience and sustainability of the European manufacturing ecosystem.

Production Showcase

Explore our innovative magnetic core production process.

Collaborate with us to lower carbon emissions

Explore the innovative ZECO₂RE magnetic cores that promise zero emissions and maximum efficiency. Get in touch today to discover how our cutting-edge sorting and laser cutting solutions can lower your environmental impact.